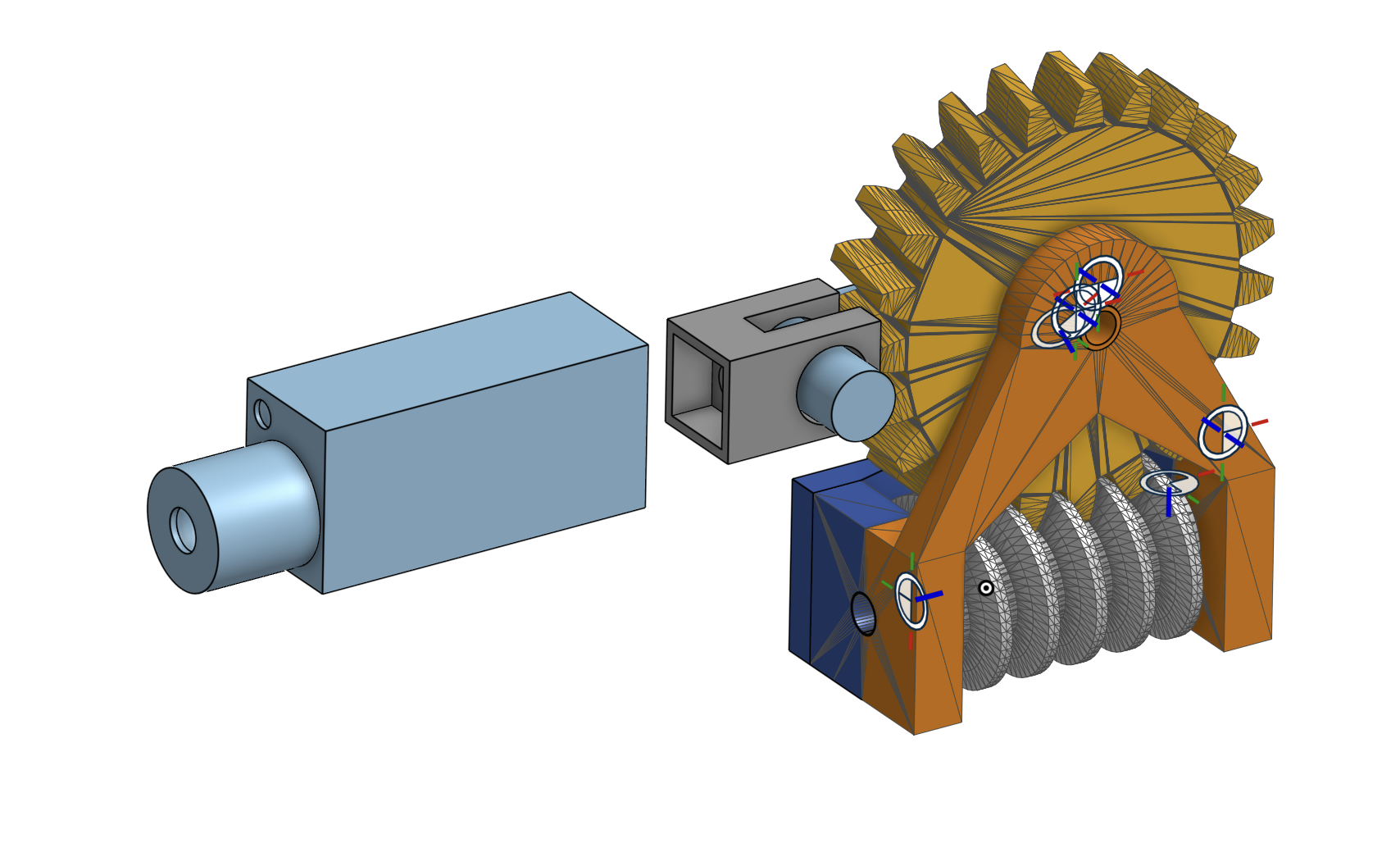

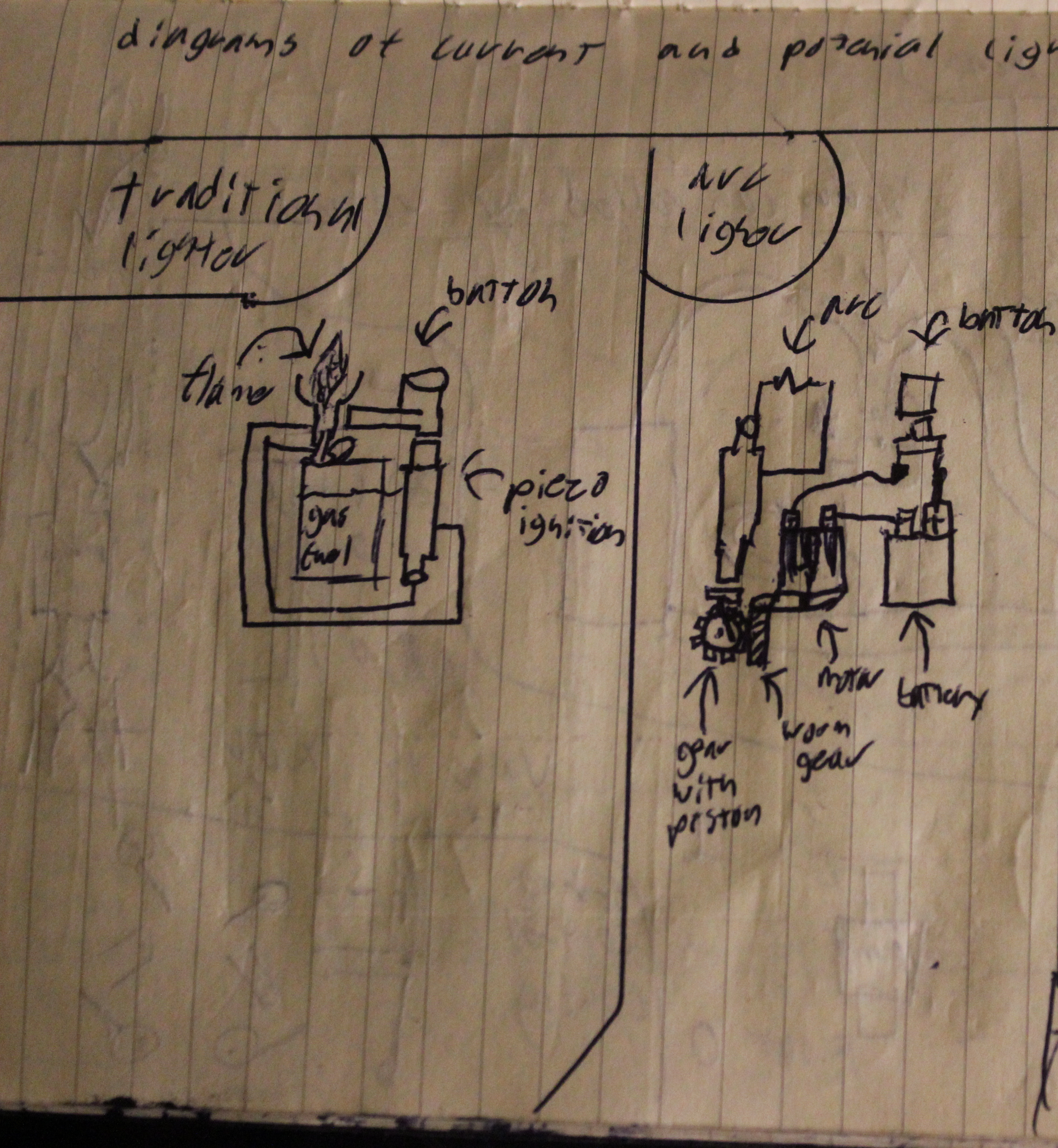

diagrams of current and some possible lighters (not all shown)

Ideation

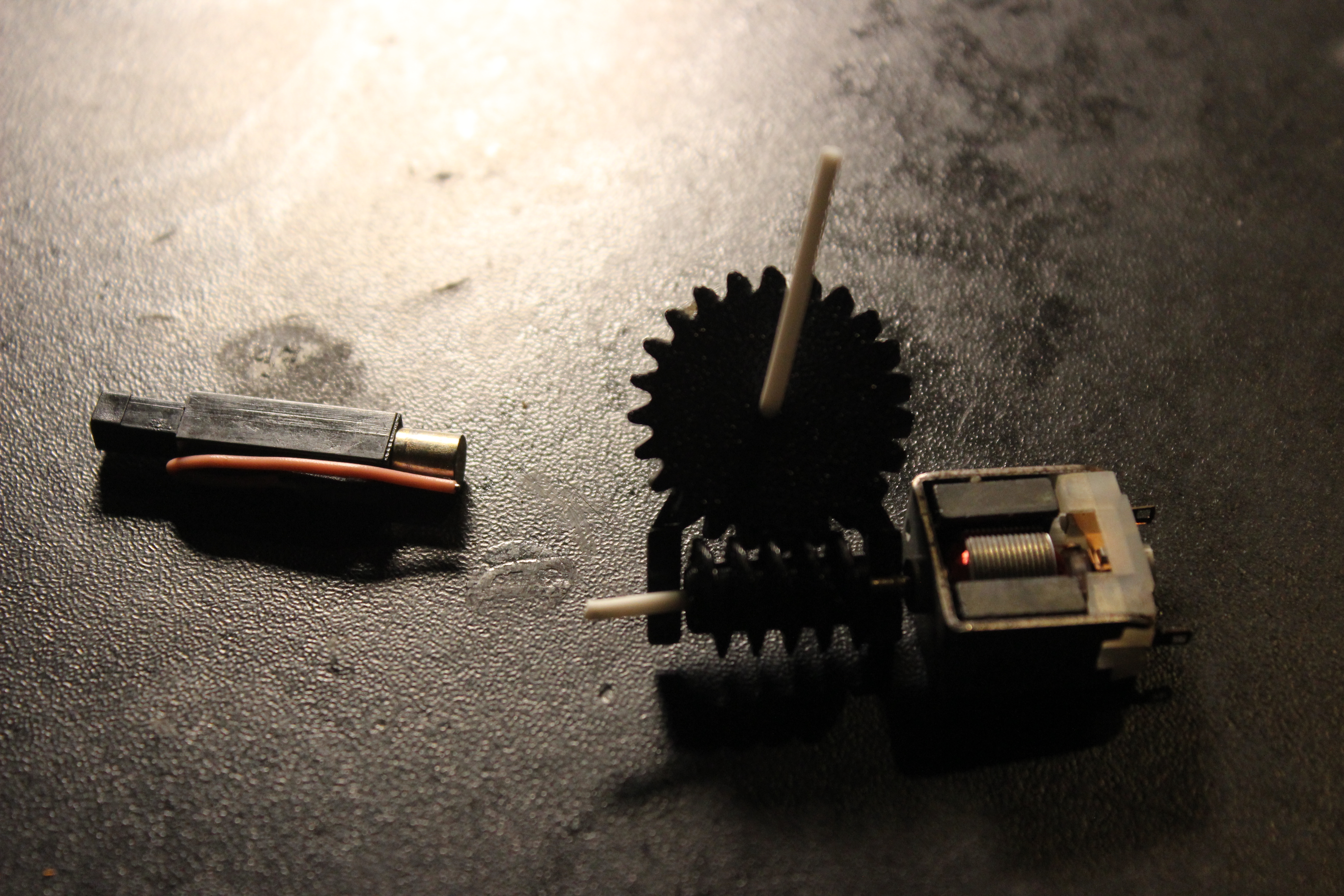

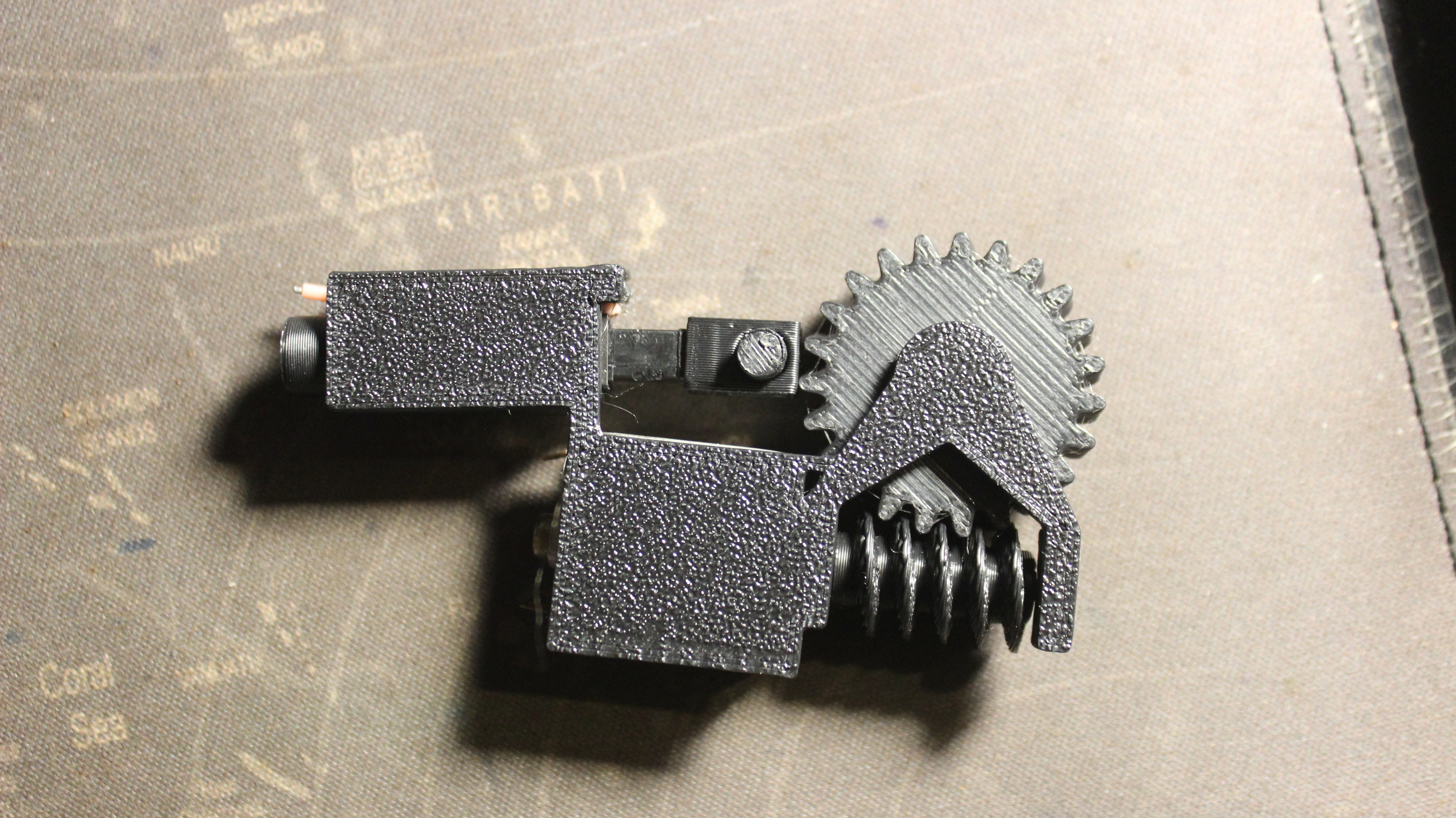

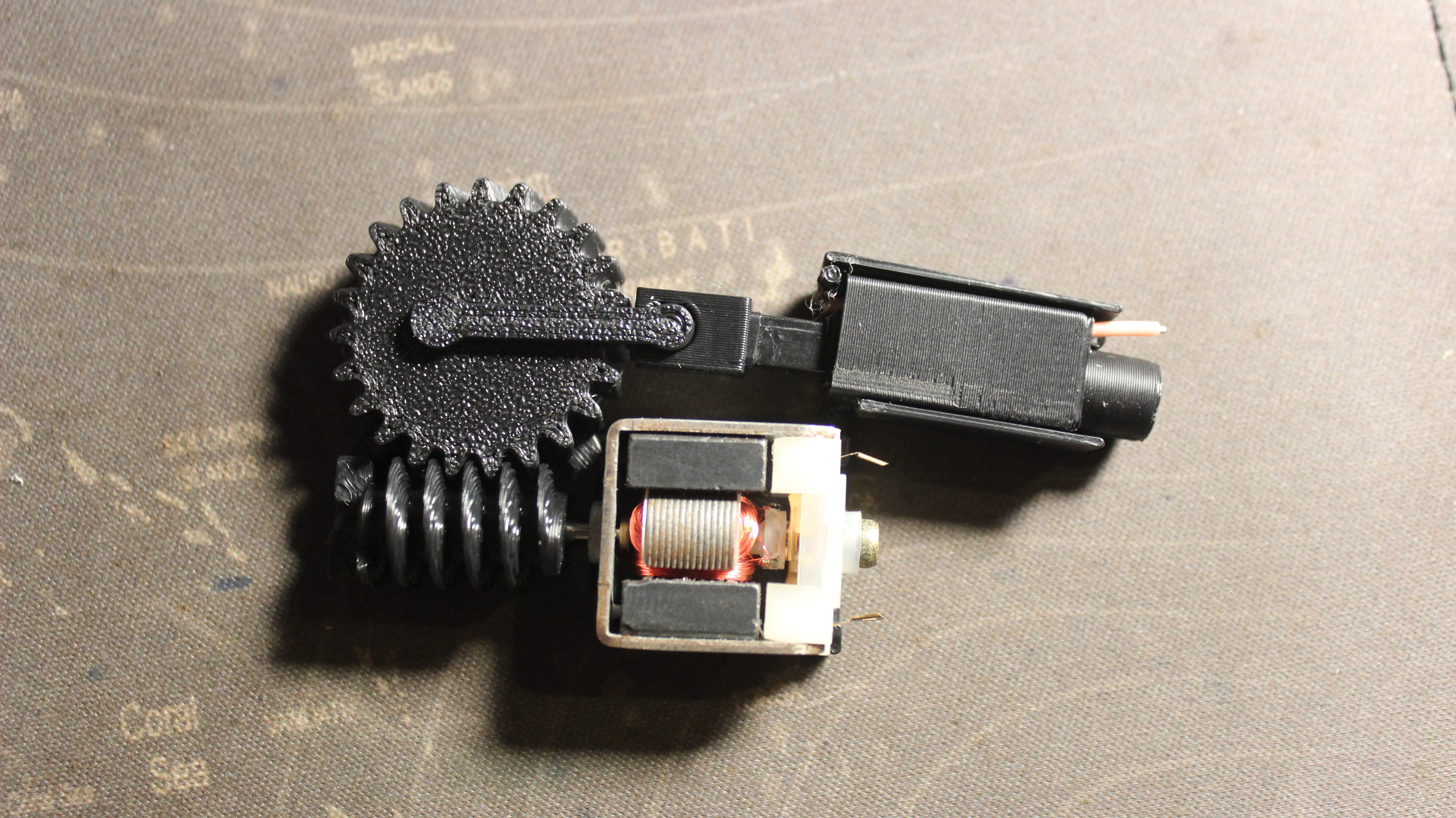

I've been doing a lot of research regarding lighters and i see of lot of potential in studying them and trying to improve on them. for this project i will be creating a RIS (rapid ignition system) that could be used in a lighter, homemade rocketry or in general controlled burns of gas or liquid propellents. This project will contain 3 major parts: the gears, the motor and the spark.