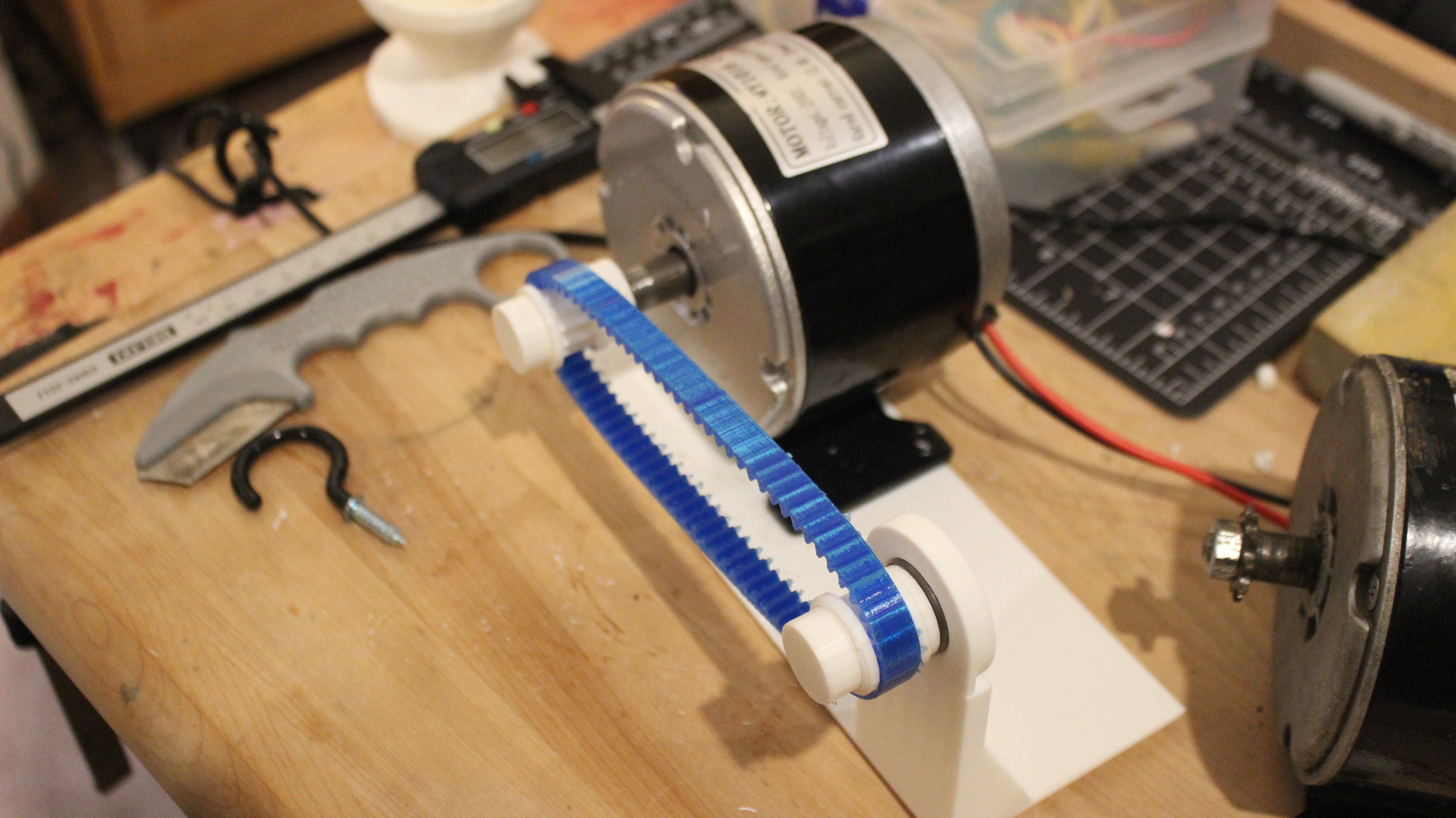

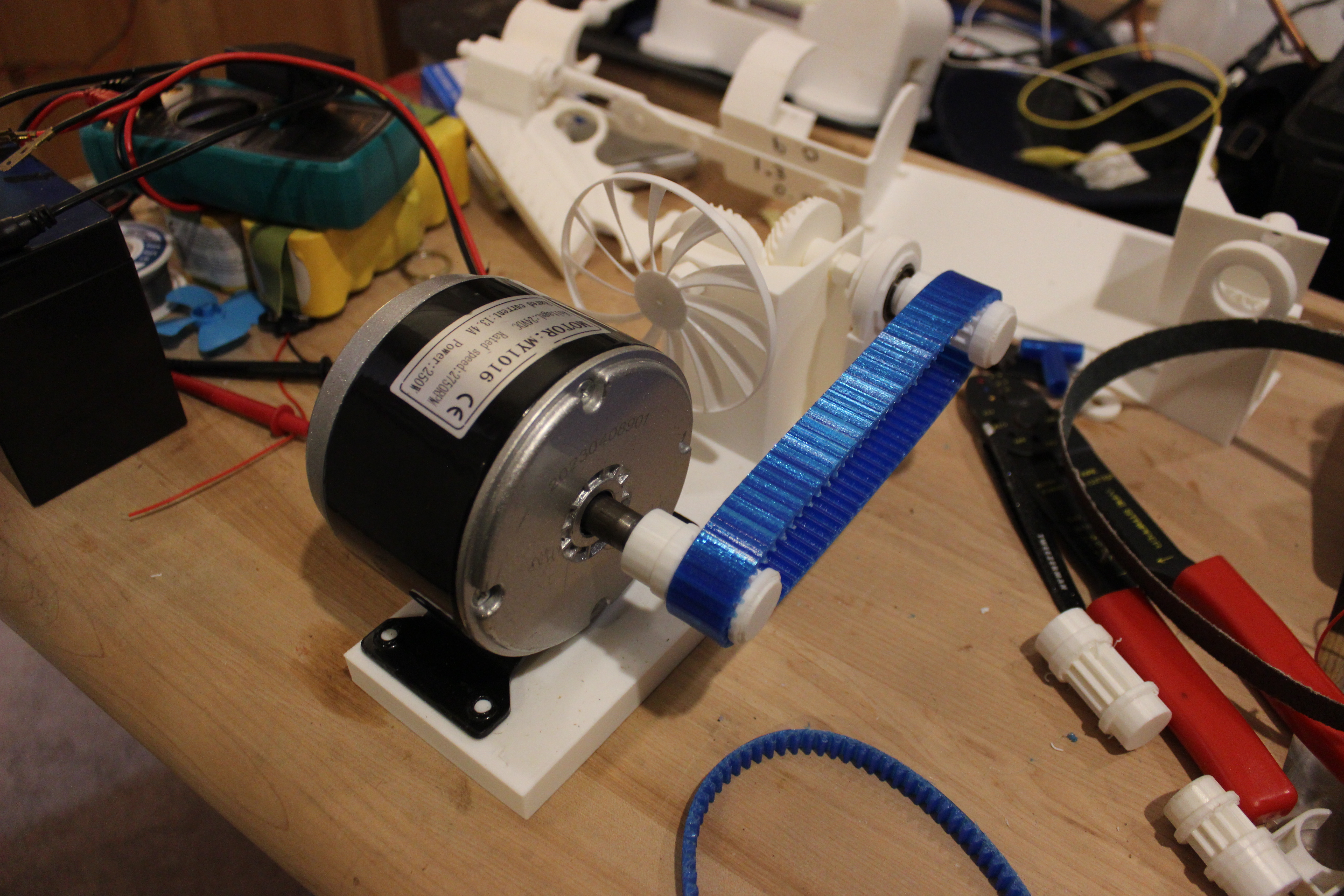

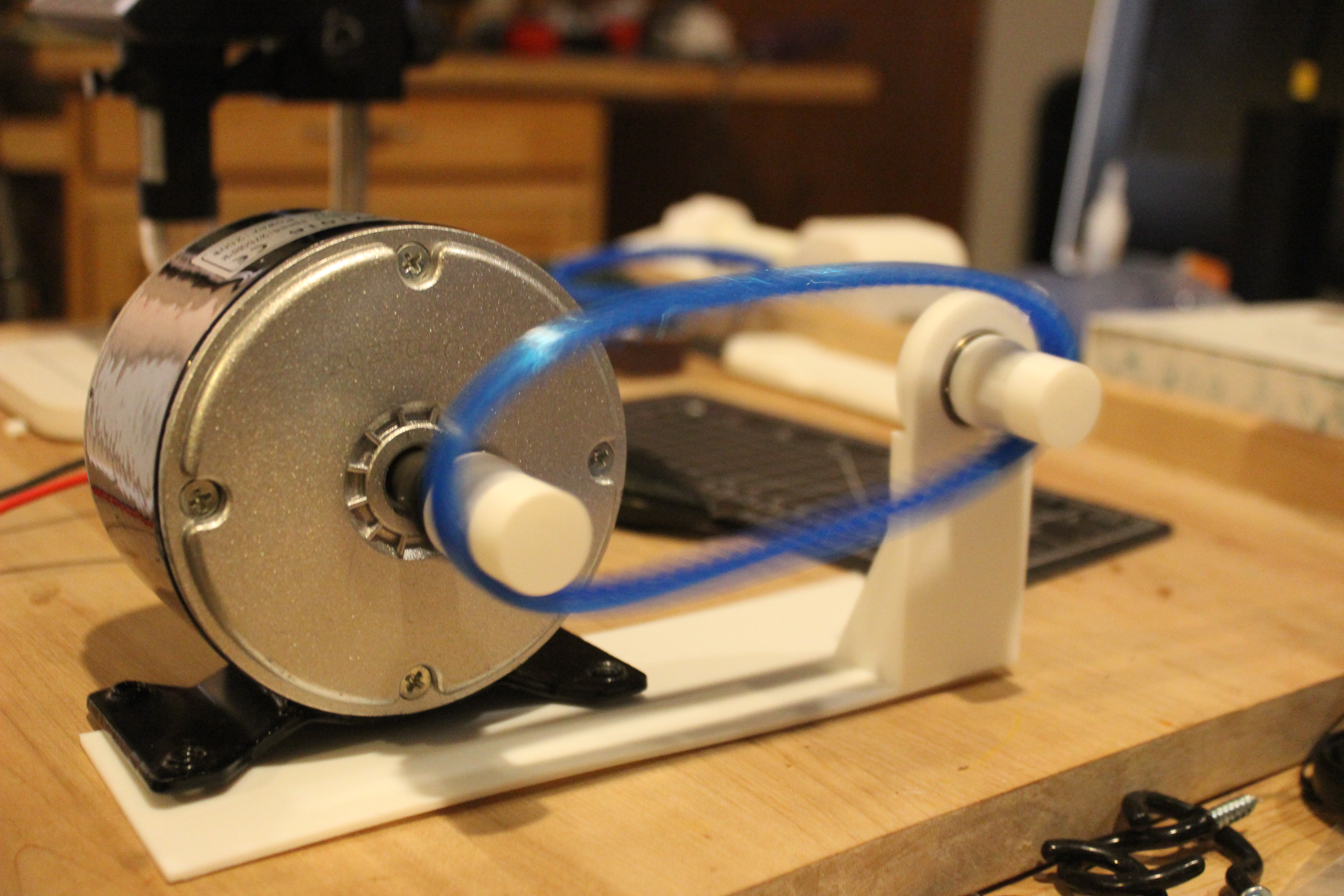

Photo of the V1

V1

This initial version was certainly "throwing stuff at the wall to see what sticks" in nature. i just wanted to model up some stuff, print it and watch what broke.

one issue you can pick up from the photo and certainly from demo videos, is that there is a lot of issues with the belt oscillation there are several factors things that are causing this to happen such as:

- Inconsistent thread on the motor leading to a nut at a slight angle that is amplified over the connecter

- The motor lying on only 2 anchor point and leaning slight over the base at a upward angle

- the ball bearing side being unweighted and therefore vibrating due to rotating and "pulling" forces from the belt

-having the belt slip off and shift around many times during demos