Materials

For this project I will converting two bottles into containers that can properly hold pressure (tested up to ~10 PSI).

one smaller bottle will not have a exit valve, while the larger soda bottle will have a barbed exit connecter.

to do this you I used:

general:

1 large soda bottle

1 small water bottle

1 air compressor (manual or automatic)

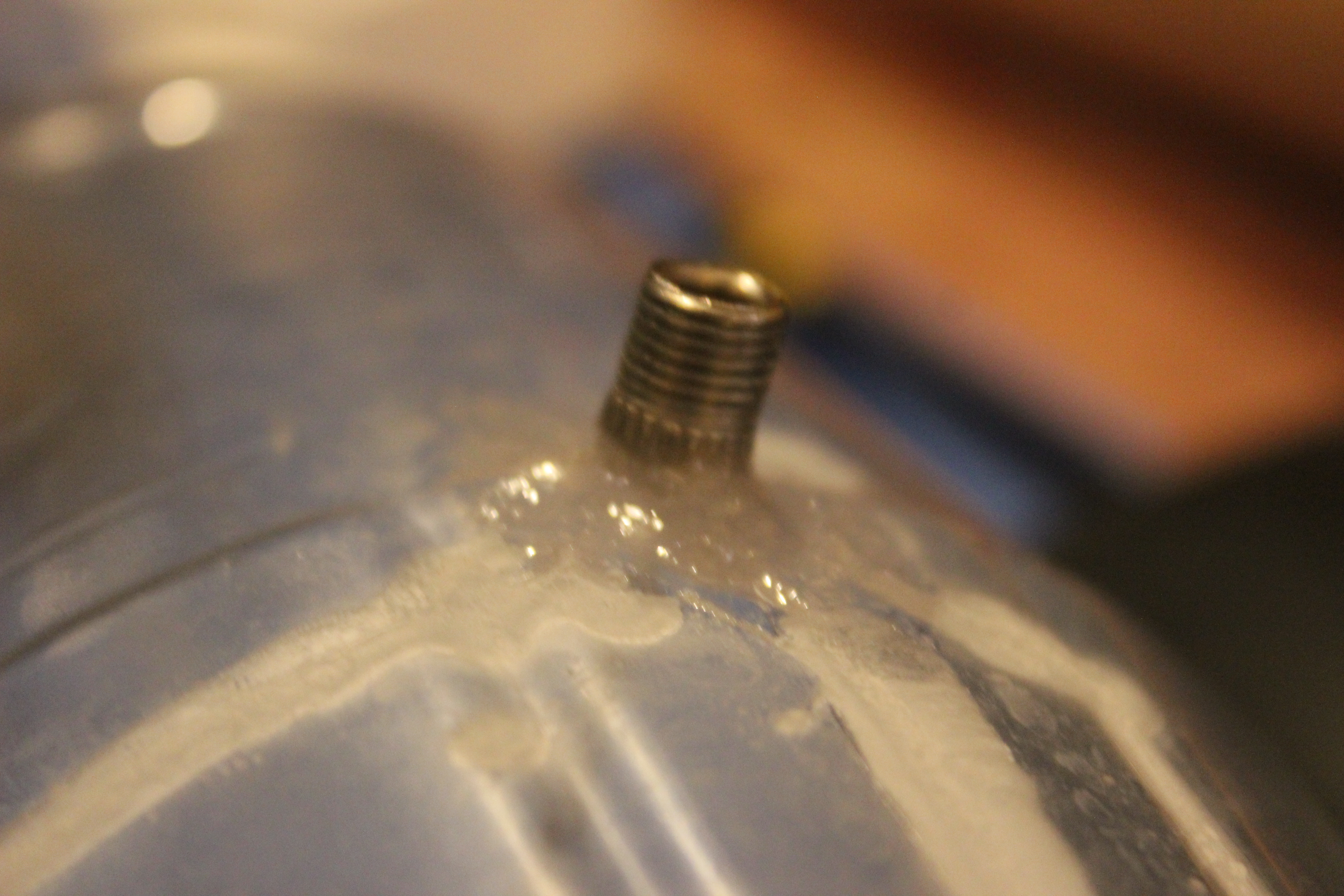

1 3d printed barbed exit cap

1 ball pump needle

sealants:

super glue (larger gaps)

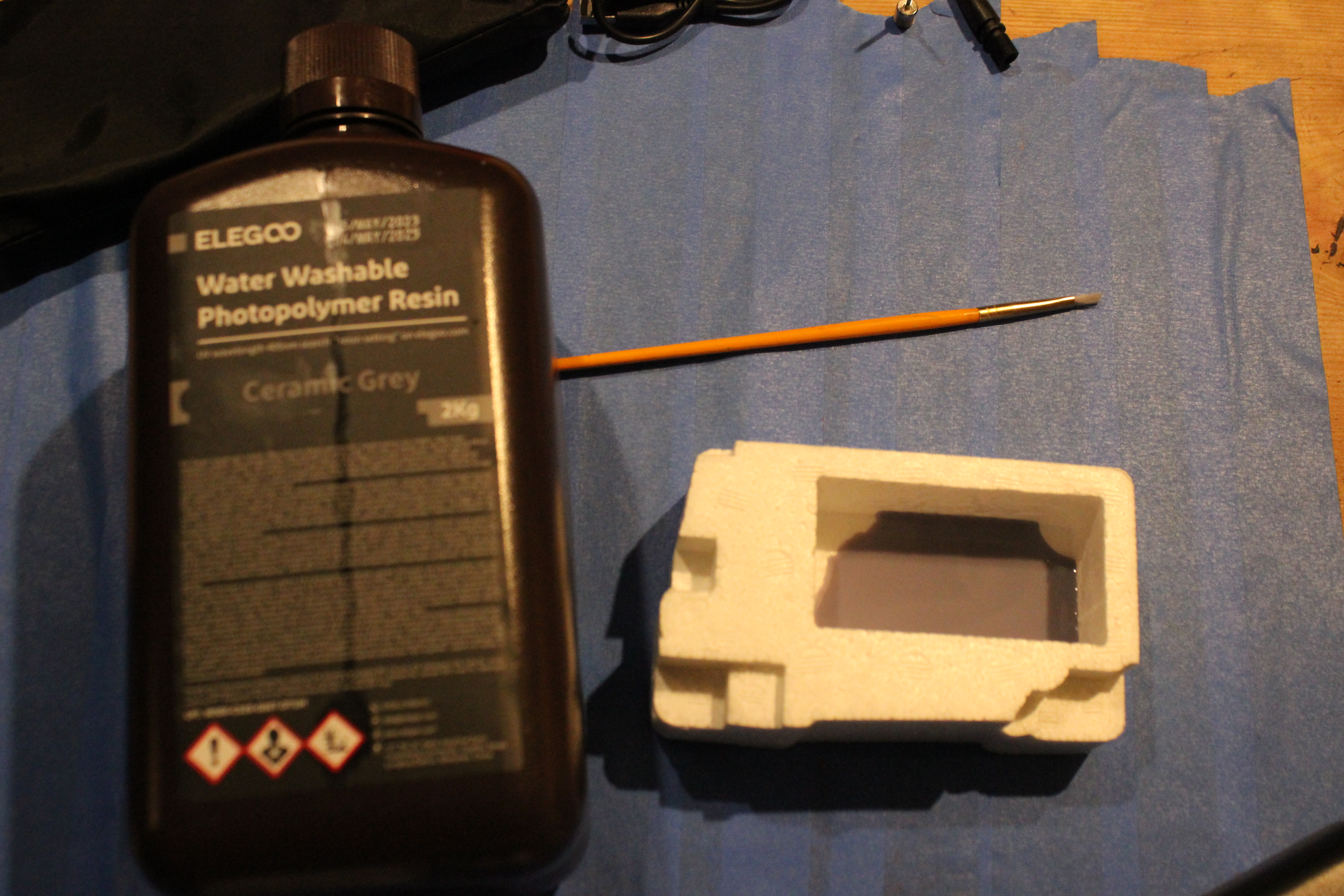

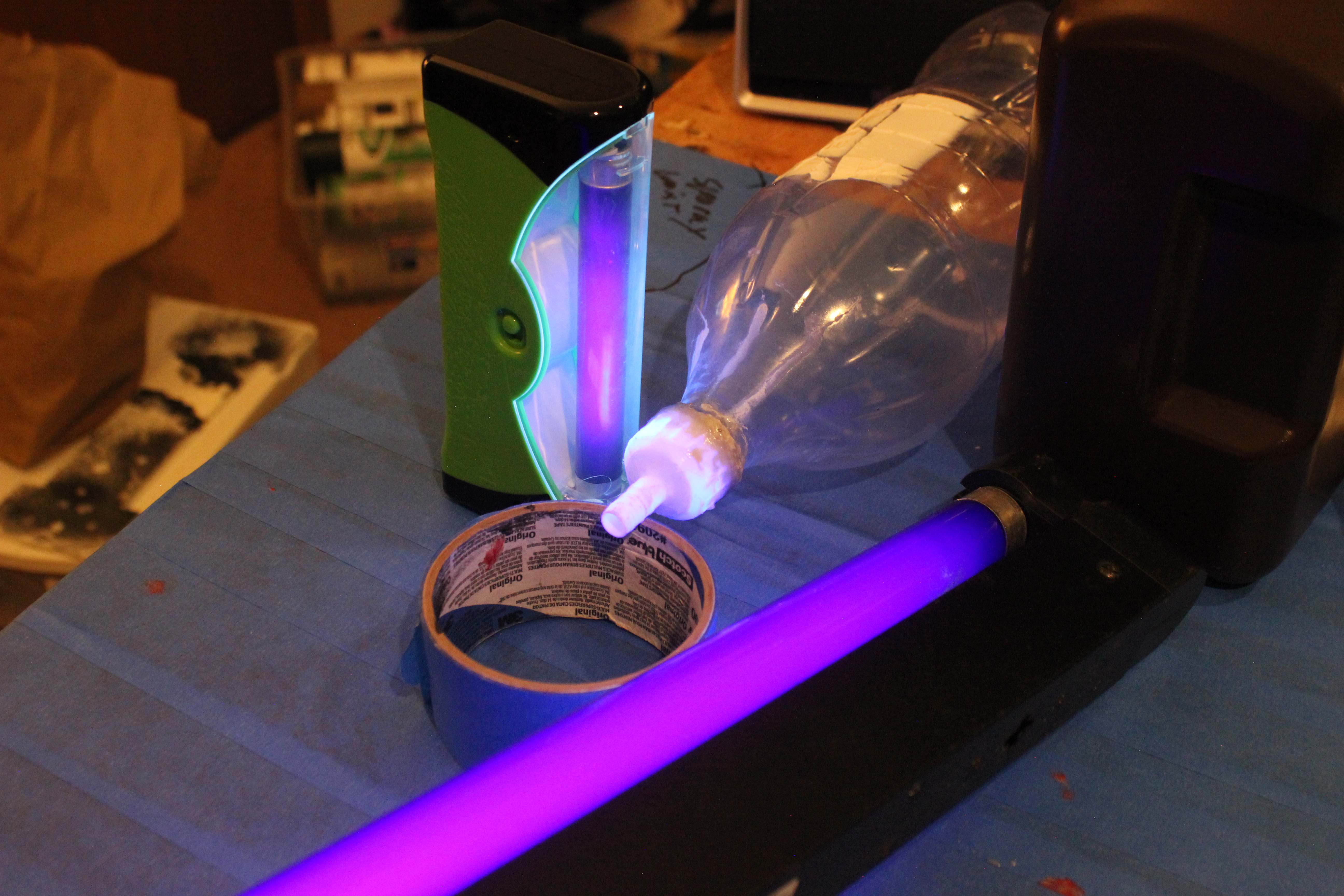

UV resin (smaller air tight gaps)

safety equipment (if using UV resin):

nitrile gloves

half-face respirator