Version 0.1

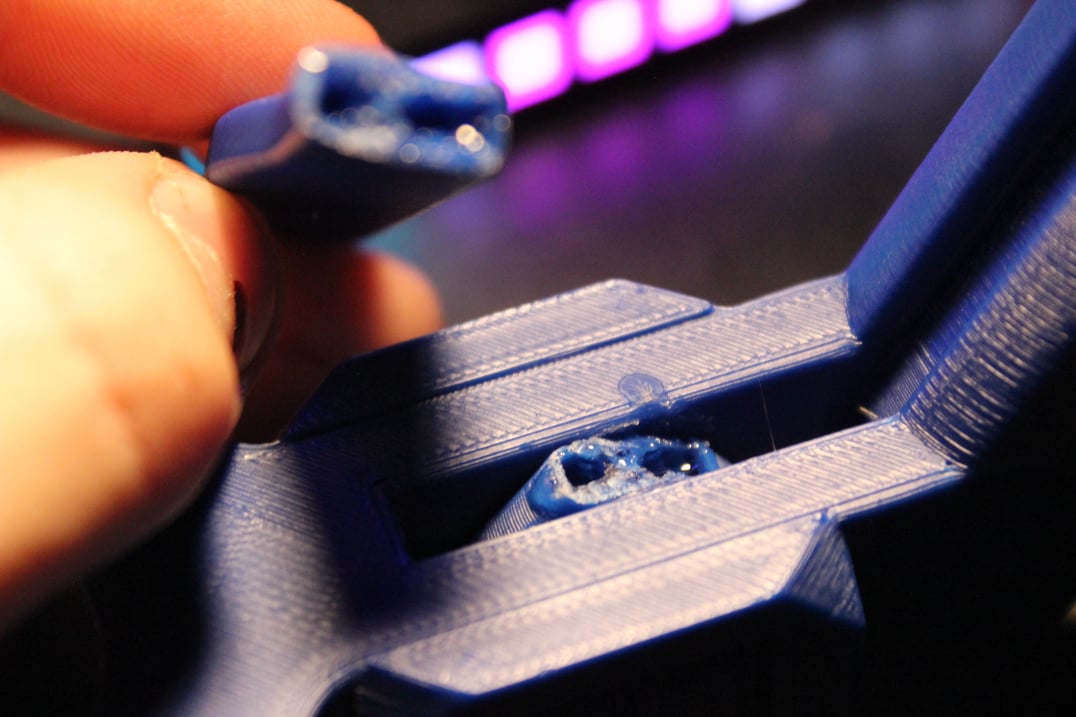

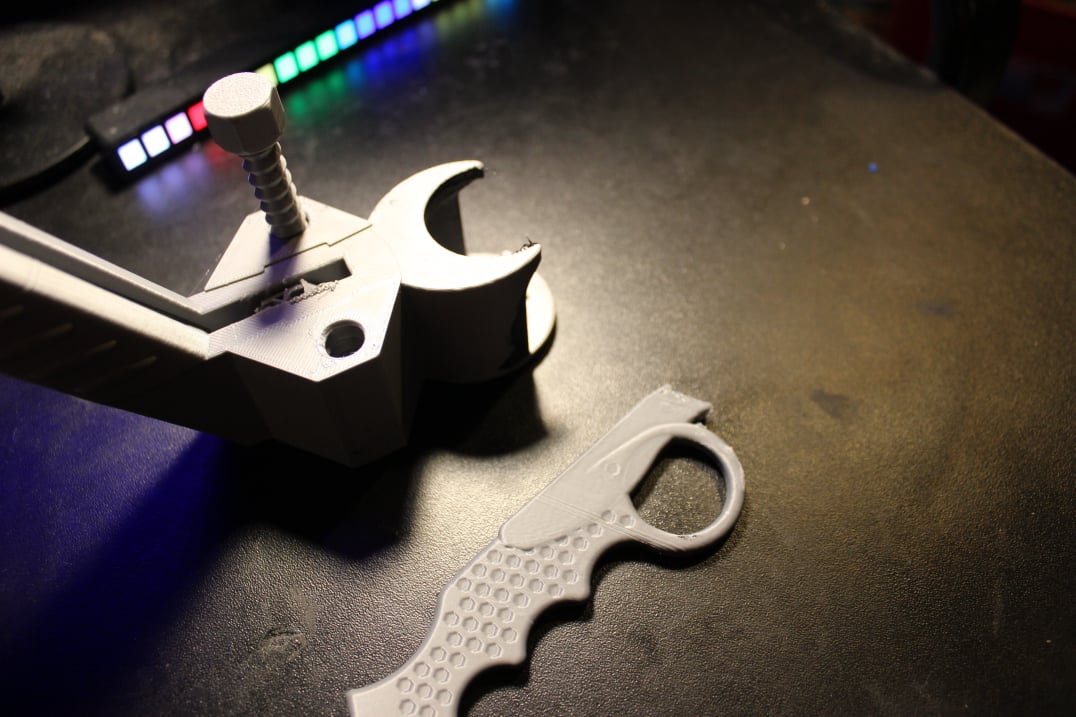

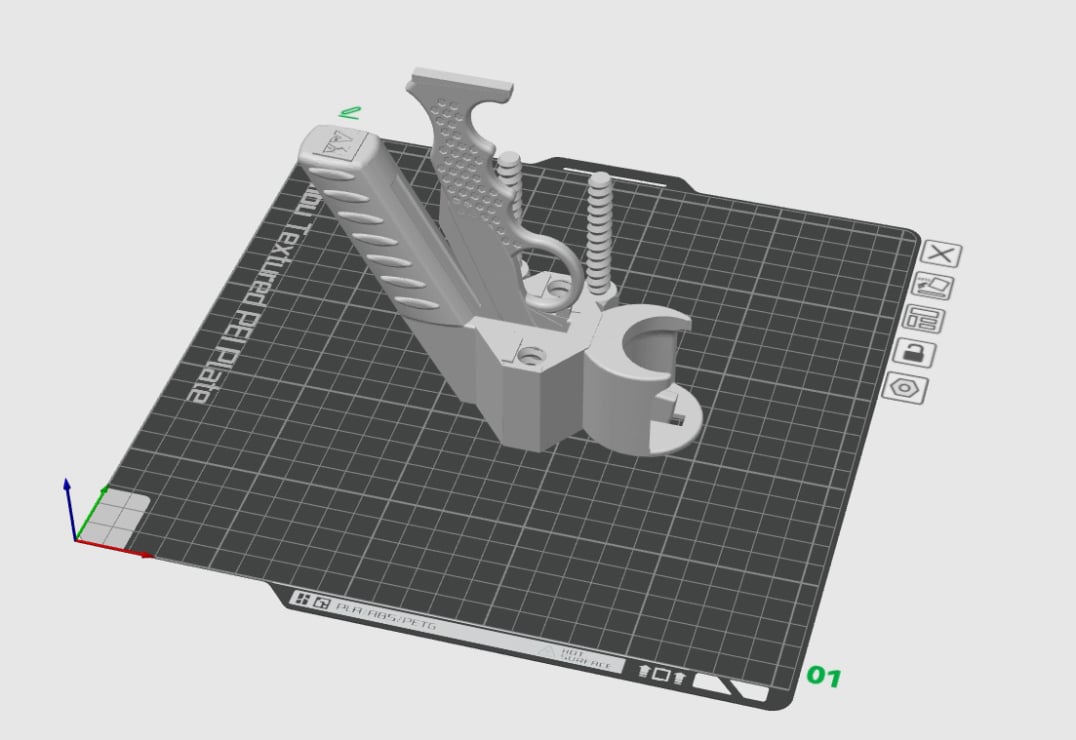

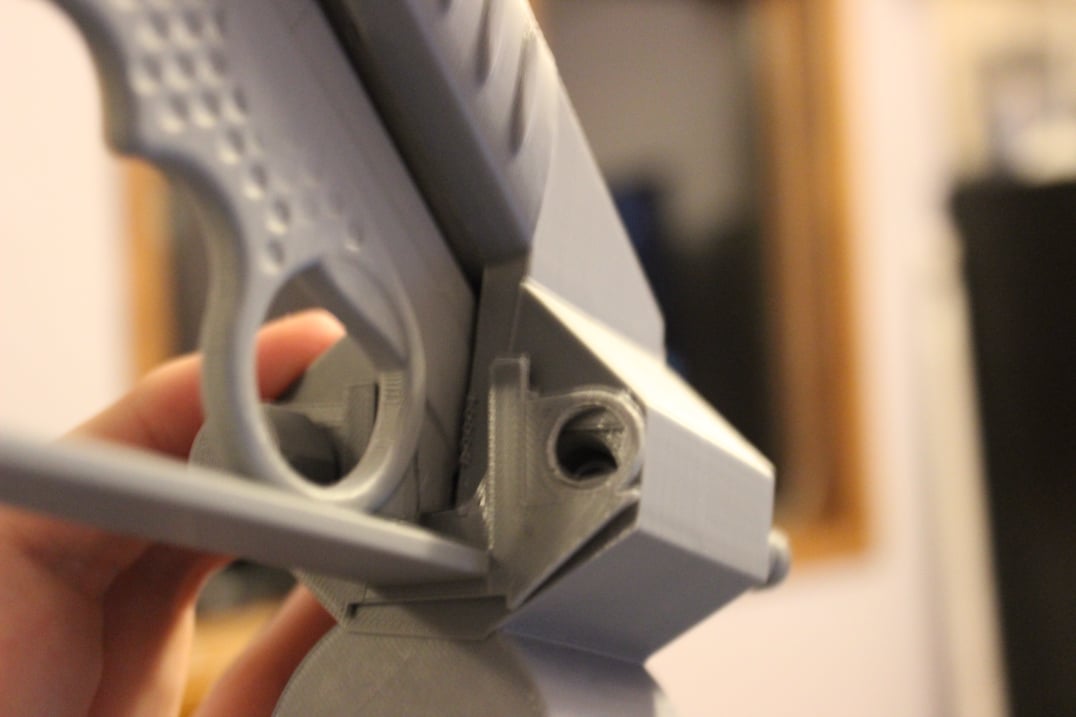

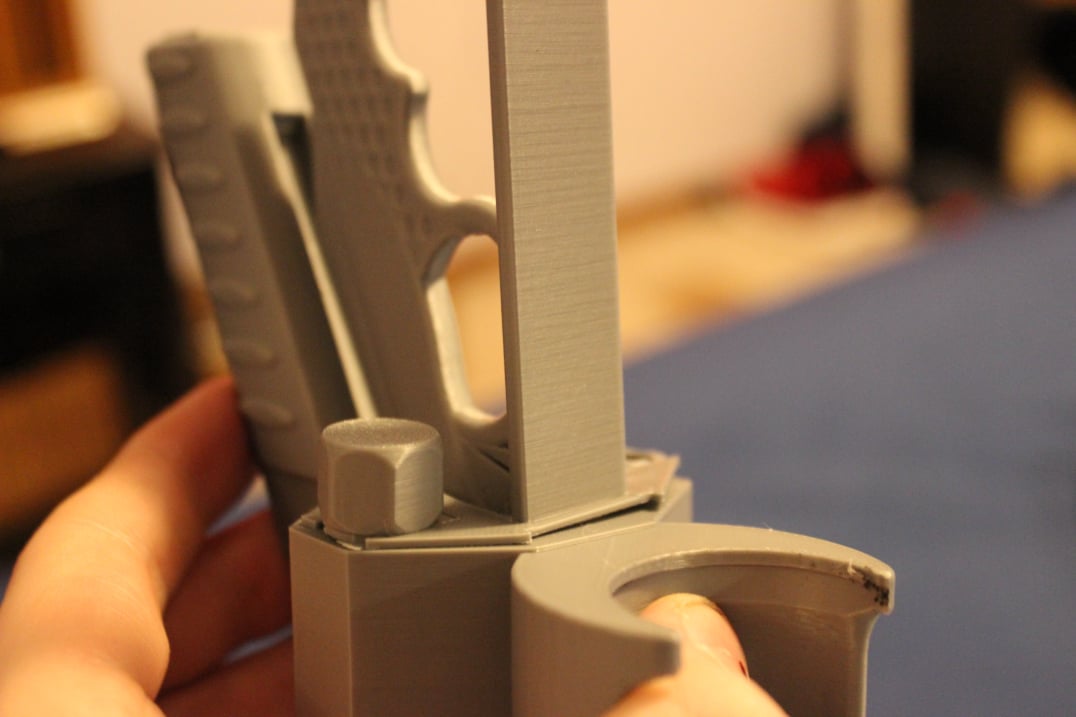

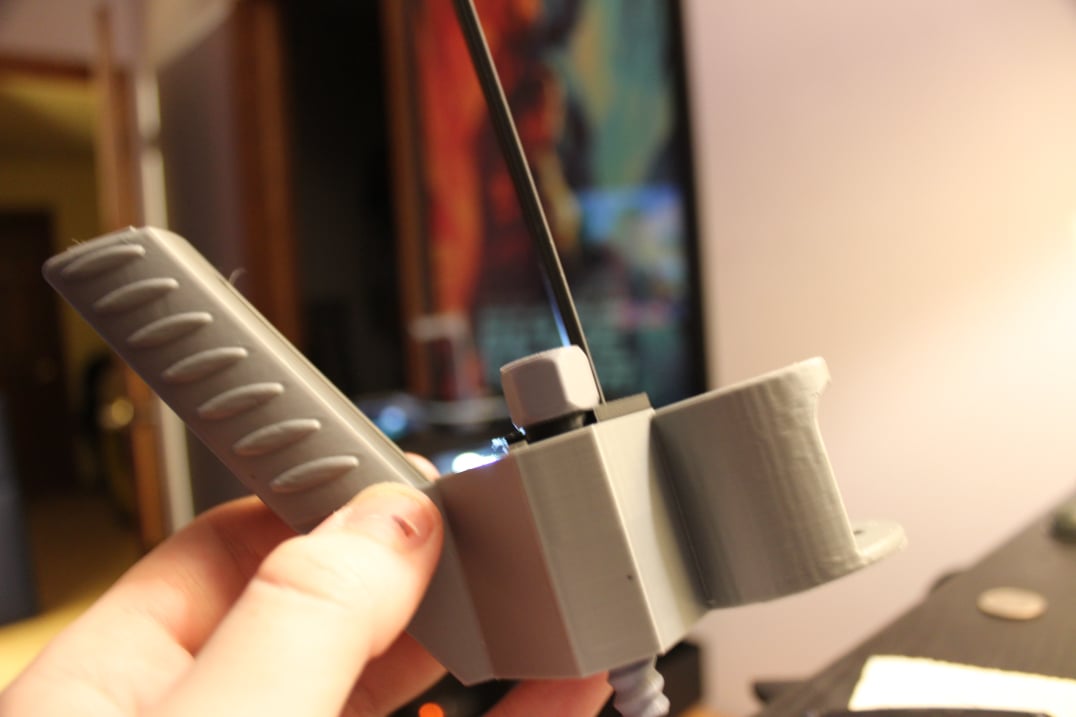

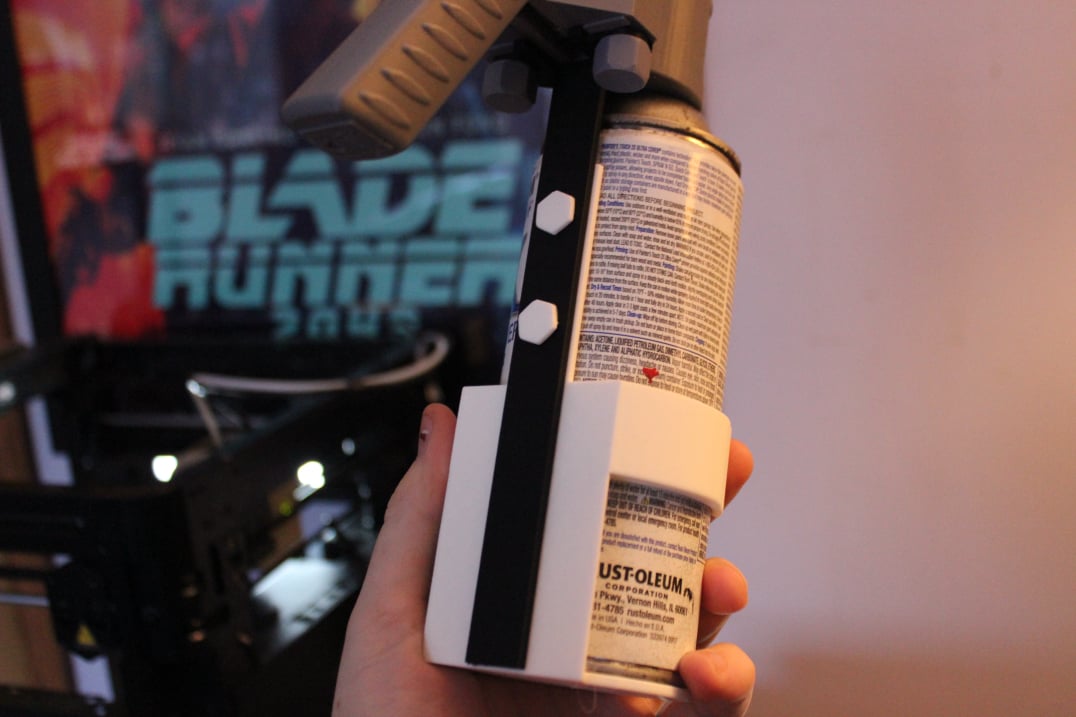

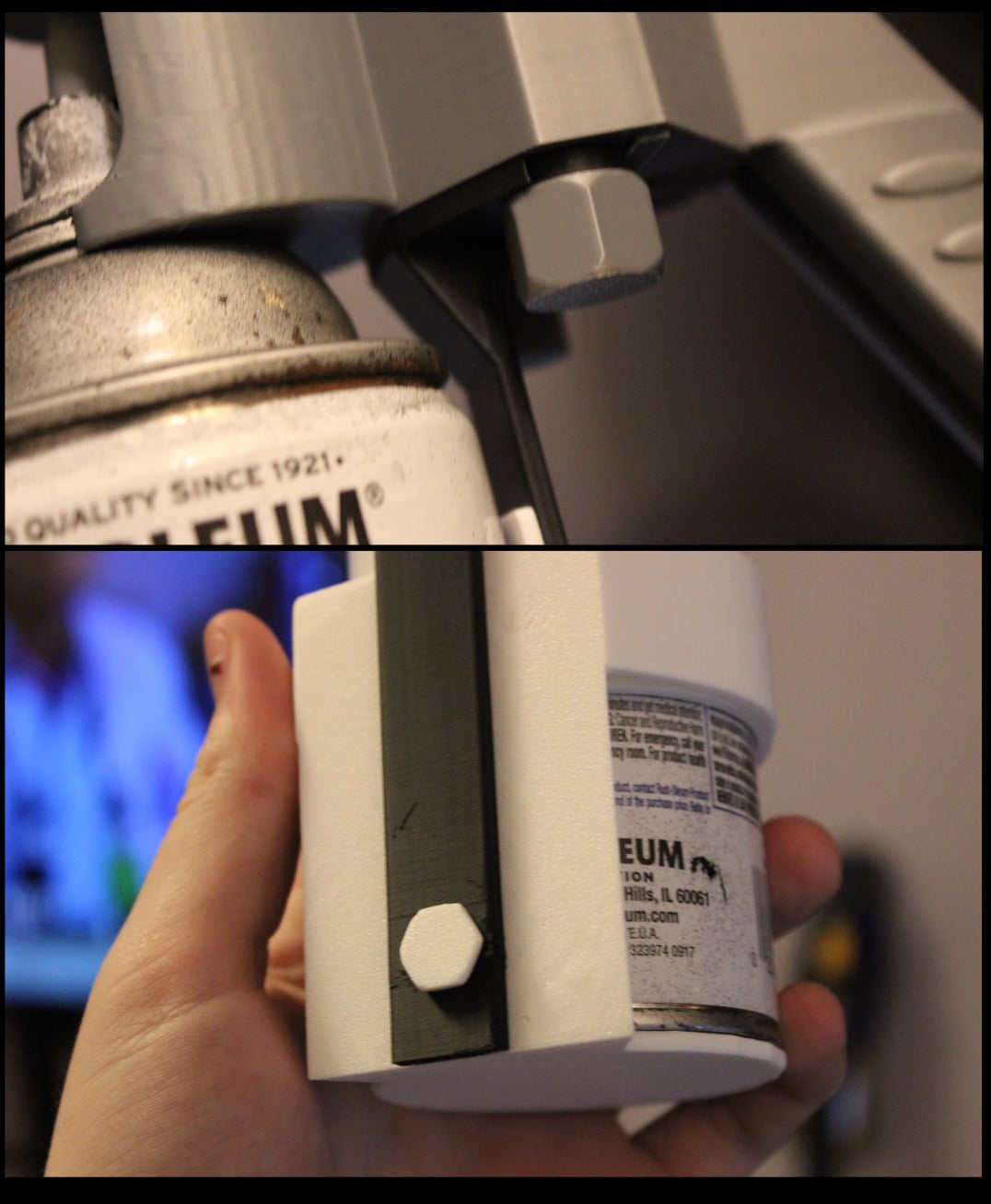

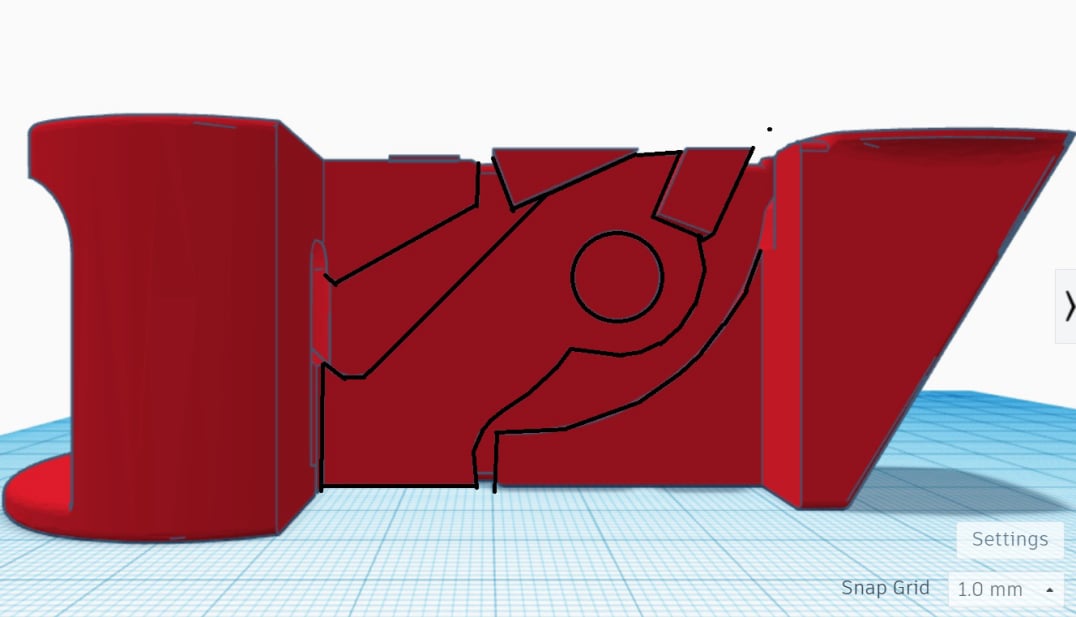

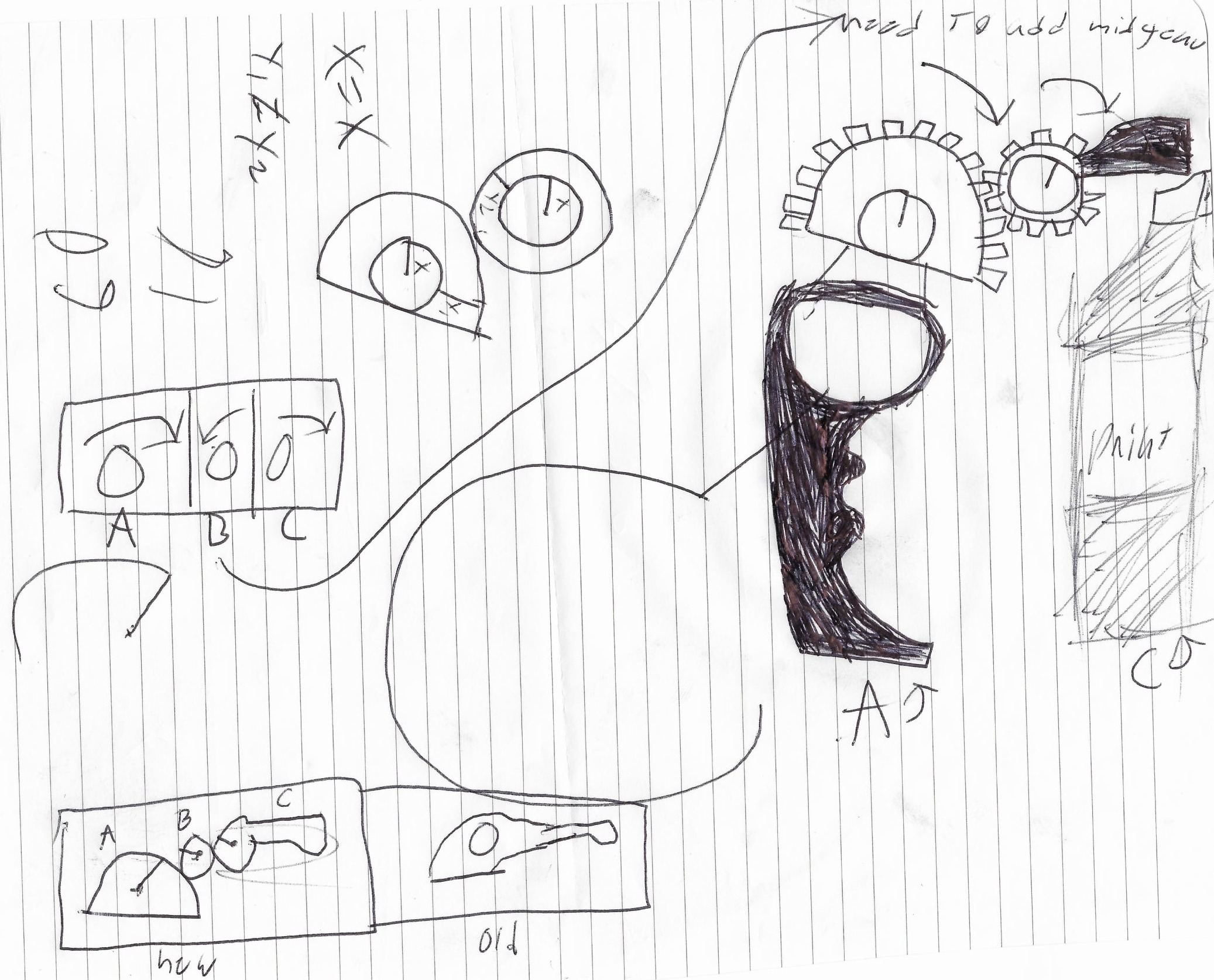

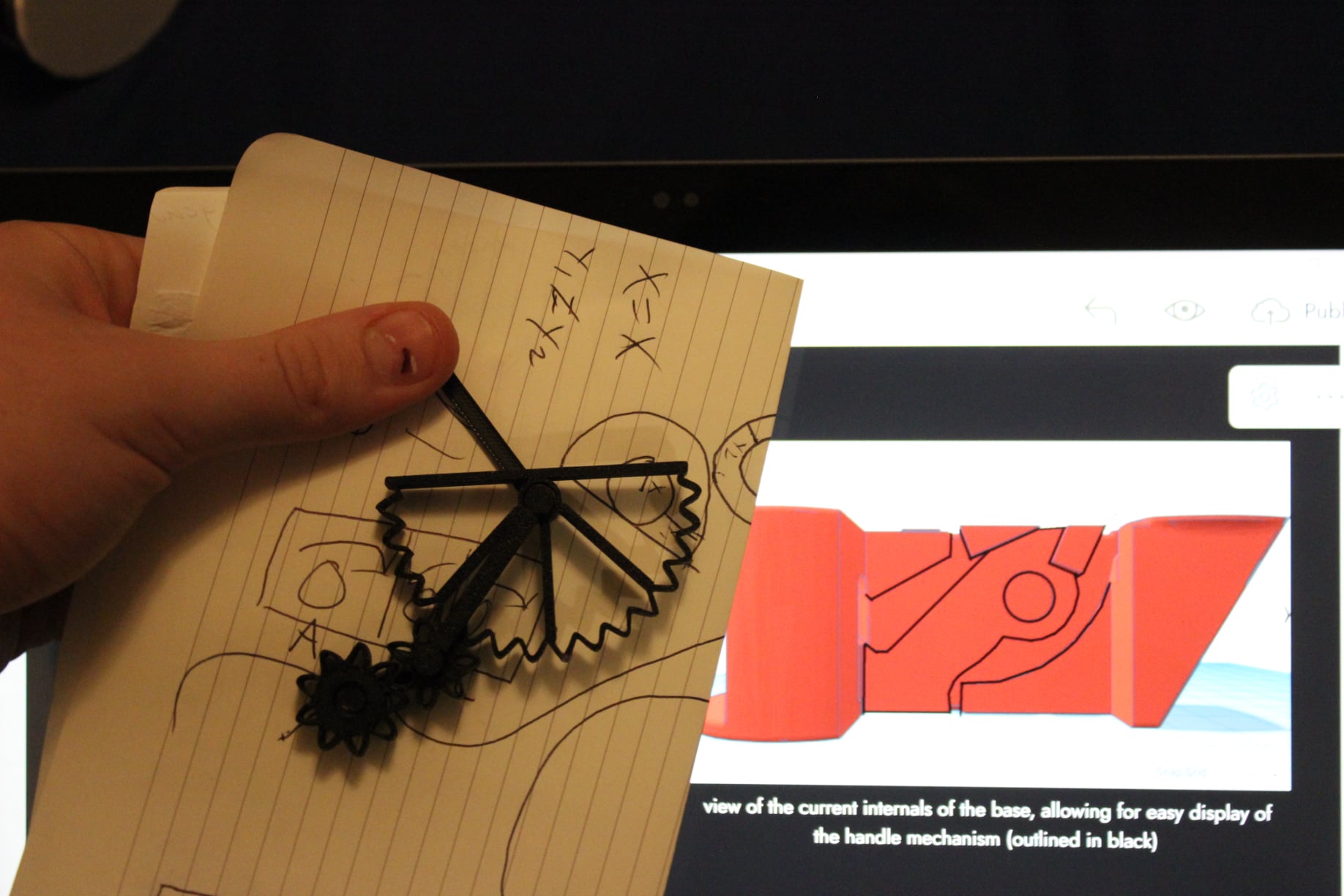

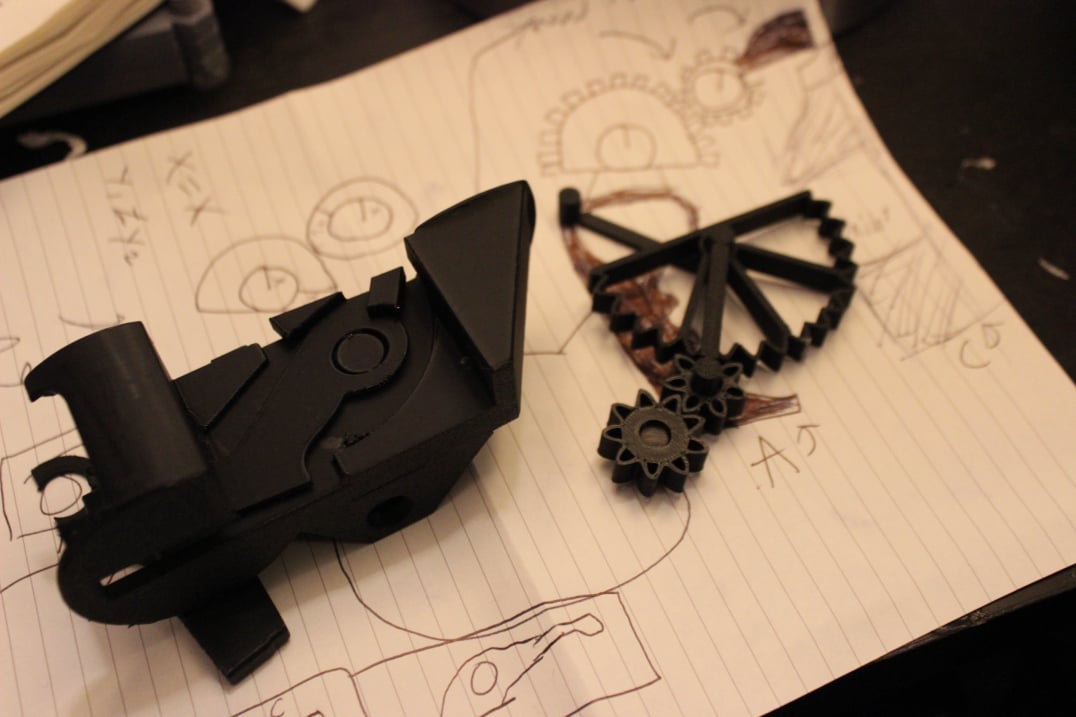

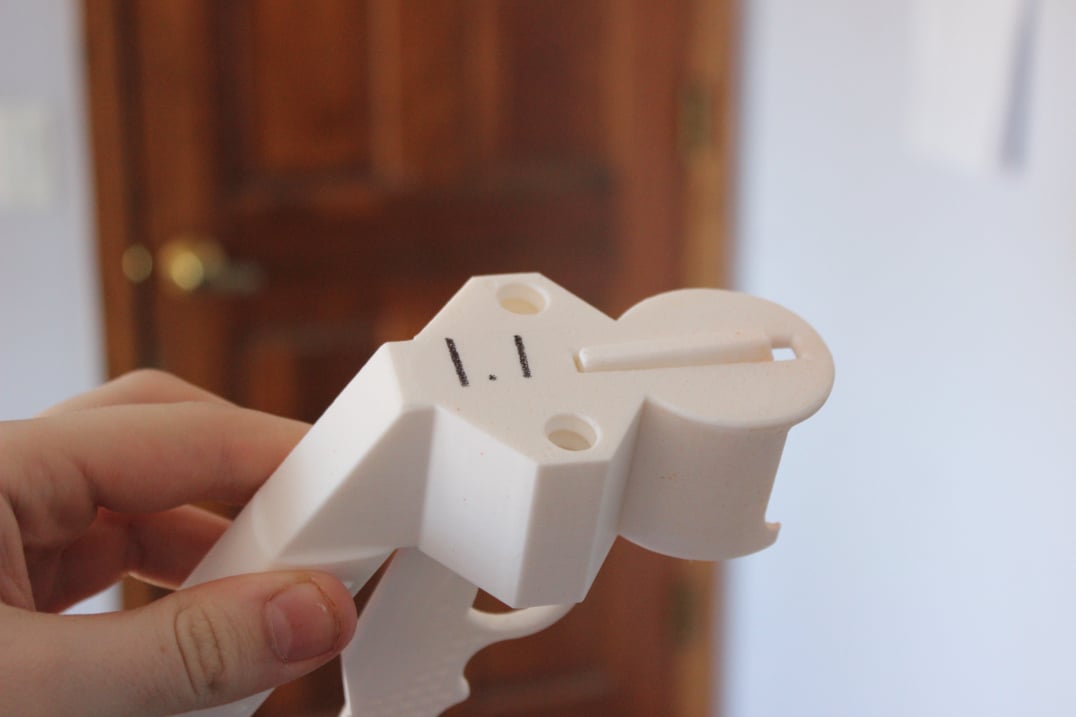

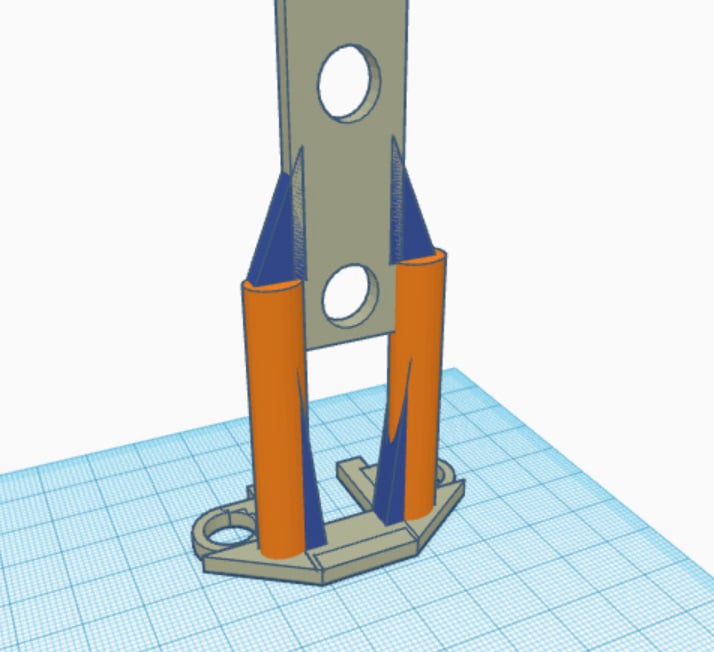

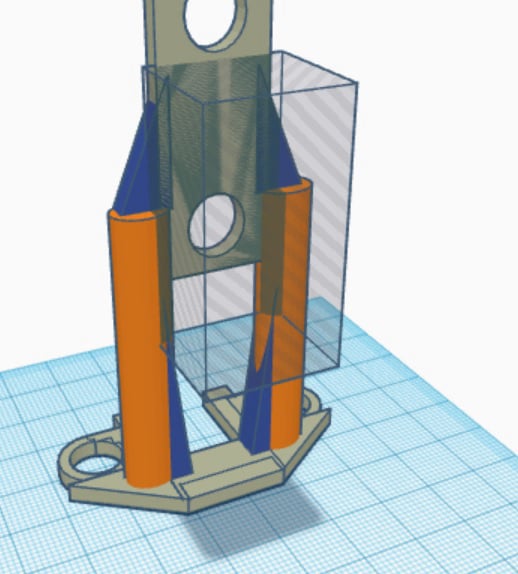

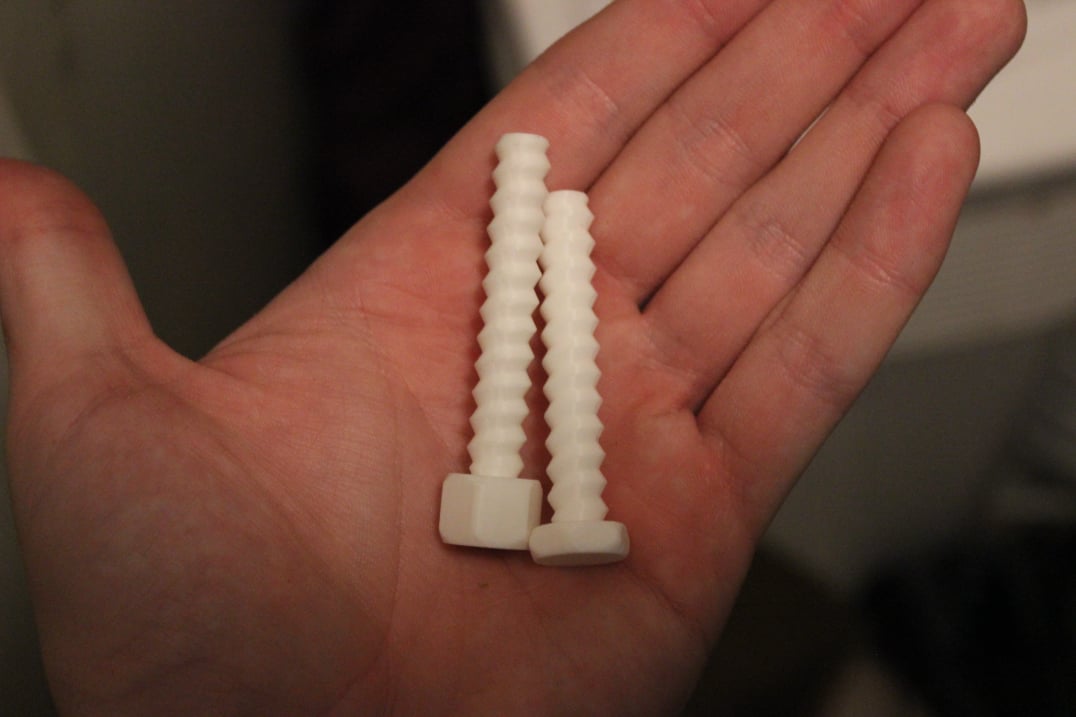

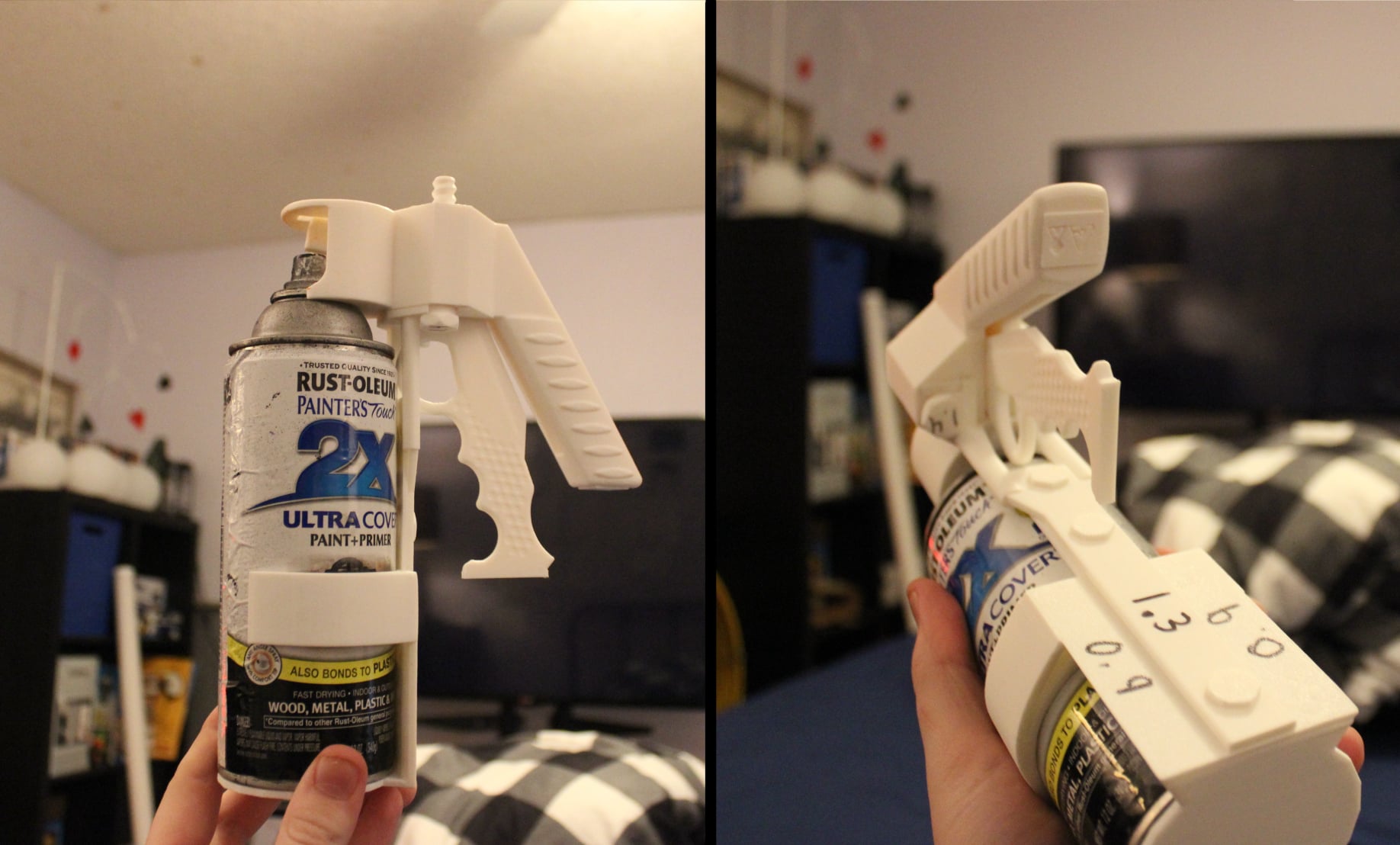

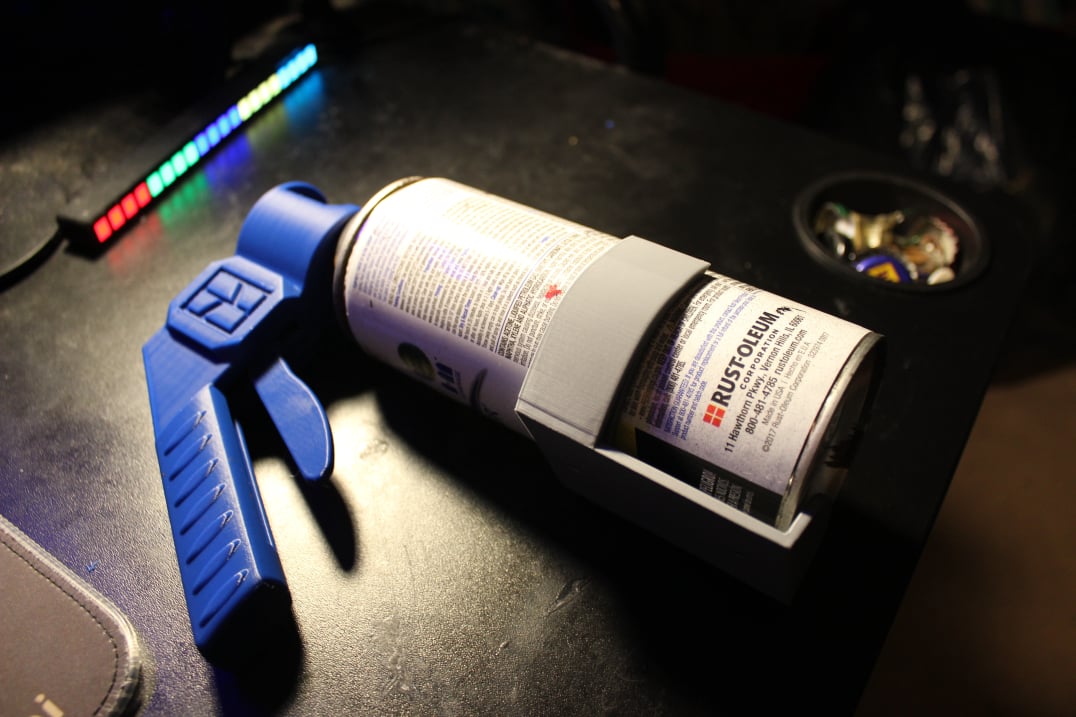

this was a extremely basic model of a spray paint mount I found online. the can was extremely unstable and the handle was very weak and broke upon any attempt to use it. my goal is to make a proper easy to use version and make it easier to print on more printers. i plan to add a ring hole and proper grooves to the handle. remove the unneeded side logo to reduce the chance of print failure. add a secondary mount system to improve stability that attaches through a nuts and bolts system. add a circle base so the system can lie flat on it's bottom.

and of course, add my own logo :0